This thermostat and motor belonged to a device called a thermo-electric damper-regulator and alarm, otherwise known as a “damper flapper.” It was the predecessor of the modern thermostat and established the technology that laid the foundation for the automated control industry. Honeywell, a company with well-known ties to Hennepin County, also traces its roots back to the invention of this device that was invented by Albert M. Butz (1849-1905).

Butz immigrated to the United States from Switzerland in 1857 and was living in Minneapolis when he was awarded a patent for the damper flapper in 1886. That same year he formed the Butz Thermoelectric Regulator Company. After a series of name changes, mergers, and acquisitions, it eventually became the company we know today as Honeywell International Inc.

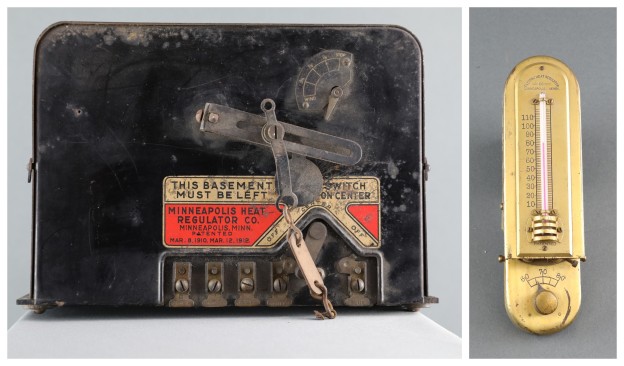

The damper flapper was a system that controlled coal fire furnaces. When the temperature inside a home became too cold, Butz’s invention would lift the damper on the furnace, allowing air to fan the flames, thus automatically increasing the temperature of the residence. The device was composed of three components, a thermostat, a battery, and a motor.

The brass oblong thermostat in our collection displays the words, “Electric Heat Regulator Co. Minneapolis, Minn.,” engraved in the upper portion. In 1900, this was the name of the company that would later become Honeywell.

The motor encased in black metal came from a damper flapper produced in 1912. At this point in Honeywell’s history, the company’s name was The Minneapolis Heat Regulator Company, which is displayed at the front of the motor. In 1927 The Minneapolis Heat Regulator Company merged with Honeywell Heating Specialties Company of Wabash, Indiana. At that point the company name became Minneapolis-Honeywell Regulator Co. The corporate name would finally be changed to Honeywell Inc. in 1964.

The inventor of the damper flapper would not stay in Minnesota long, nor with the company he started. After transferring the patent to his investors in Minneapolis, Butz moved to Chicago. He would later patent eleven more inventions, but this damper Flapper remains his most groundbreaking and significant contribution in the field of automated temperature control. Accordingly, he was inducted into the Minnesota Inventors Hall of Fame in 1992. Butz’s invention was not only innovative but became the cornerstone of the most iconic thermostat company in the world.

Written by Alyssa Thiede

Sources:

Minnesota Inventors Hall of Fame. “Albert M. Butz- 1992 Inductee” MinnesotaINventors.org. http://minnesotainventors.org/inductees/albert-m-butz.html (accessed September 28 2018.)

Larson, Don W. “Land of the Giants: A History of Minnesota Business.” Minneapolis: Dorn Books, 1979.

Rodengen, Jeffrey L. “The Legend of Honeywell.” Fort Lauderdale: Write Stuff Syndicate, 1995.

http://startribune.newspapers.com/image/189833914

Our Honeywell collection was inventoried and cataloged as part of our larger collections inventory project. This publication was made possible in part by the people of Minnesota through a grant funded by an appropriation to the Minnesota Historical Society from the Minnesota Arts and Cultural Heritage Fund. Any views, findings, opinions, conclusions or recommendations expressed in this publication are those of the authors and do not necessarily represent those of the State of Minnesota, the Minnesota Historical Society, or the Minnesota Historic Resources Advisory Committee.